CSR

Basic policy

As “a good corporate citizen,” Ise Chemicals complies with all laws and regulations and promotes fair and honest business activities based on social norms, while remaining mindful of protecting the environment and conserving natural resources and aiming to be a company that earns the broad understanding of society.

Based on this basic management policy, we recognize that safety is our top priority as we strive to achieve an environmentally conscious society and coexist with local communities.

Contributing to local communities

What measures is the company taking to communicate with the local communities?

The employees of Ise Chemicals carry out activities that are closely tied to the local communities, such as by participating in and supporting cleanup and beautification activities in the areas and local communities near our factories, as well as sponsoring local events, such as sporting events and festivals.

In addition, we also offer tours of our factories to local residents and students from nearby schools.

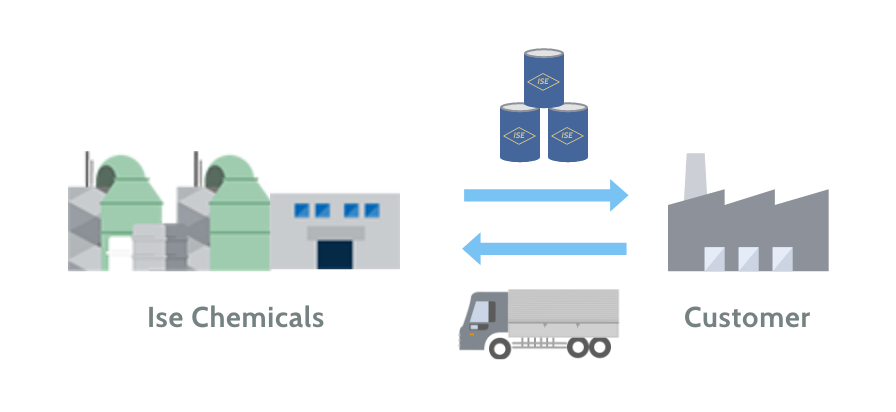

Recycling business

What is the company doing to make effective use of natural resources?

In order to effectively use iodine, which is a precious natural resource, we collect iodine that has been used for catalysis, etc. from our customers and recycle it into iodine products.

Global support

What types of social contribution activities, etc. is the company conducting outside of Japan?

We are donating iodine in cooperation with the Japan Iodine Industries Association, Chiba Prefecture, etc. The iodine is provided free of charge for countries and regions where iodine deficiency is a public health problem. The provided iodine is processed locally into iodized salt and distributed to children and pregnant women who suffer from thyroid dysfunction.

Sustainable use of natural resources

What are some of the measures the company has implemented regarding sustainable use of natural resources?

According to an agreement with the relevant local government, the extraction of natural gas and brine is performed under appropriate production control and monitored through constant measurements by GNSS and periodic level measurements.

In addition, after the iodine is extracted, some of the brine is pumped back underground as a measure to control ground movement.

Factory safety measures

What is the company doing for health and safety management in the factories?

We have established a health and safety committee at each factory. Risks are identified and evaluated before a problem occurs, and factory safety measures are implemented through the concerted efforts of the employees and management.In addition, the employees and management periodically patrol the factories in order to identity improvements that can be made to equipment, facilities, etc. to ensure that safety remains the top priority.

We also give guided factory tours to local residents to explain our environmental and safety initiatives while also listening to the residents so that we can incorporate their opinions and requests into the safe operation of the facilities.

By using our publicity vehicle (emergency vehicle) when a disaster occurs, we also have a system that can accurately convey information to local residents.

Measures for preventing leaks from pipelines

Leaks from the pipelines for brine and natural gas are a concern.

In addition to watching the equipment using a surveillance monitor, our employees patrol the relevant facilities daily to check them for any problems.

We also use gas detectors to periodically check for pipe leaks, and strive for early detection and early repairs of minor gas leaks.

We assess the risks according to the buried time of underground pipes, materials, records of past leaks, etc., and replace pipes in a systematic manner.

Safety measures for disasters

What are some of the measures the company has implemented in case of an earthquake or tsunami?

In case of an earthquake, if the conditions measured using the on-site seismometer meet or exceed the set conditions, the designated person can push the emergency stop button to completely stop all operations at the factory safely.

Because we have factories near the Kujukuri Coast in Chiba Prefecture and the Hyuga-nada Sea in Miyazaki Prefecture, we remain dedicated to holding regular disaster-preparedness drills for earthquakes, tsunamis, etc. in a planned manner. In particular, we continue to make steady progress in our disaster-related measures that emphasize the initial response when a disaster occurs and place the highest priority on human life and safety.

Also, the roof of the main office at the Ichinomiya Plant has been designated as a tsunami temporary evacuation site for Ichinomiya Town where local residents can take refuge in case of a tsunami, flooding or other natural disaster.

Ise Chemicals aims to carry out responsible business activities toward achieving a sustainable society.